Rosquear um furo parece simples, até você decidir entre fresamento de roscas e rosqueamento. Ambos os métodos são básicos na usinagem CNC e em operações manuais, mas atendem a propósitos, máquinas e tolerâncias diferentes. Seja rosqueando alumínio, aço inoxidável ou titânio, escolher o método errado pode significar ferramentas quebradas, peças descartadas ou horas perdidas.

Vamos analisar as diferenças reais entre fresamento de roscas e rosqueamento, quando usar um em vez do outro e como escolher a ferramenta certa para sua peça.

O que é Tapping?

Rosqueamento é o método tradicional de criar roscas internas através da inserção de um macho, uma ferramenta de corte endurecida, em um furo pré-perfurado. É rápido, fácil de configurar e amplamente utilizado em operações manuais e CNC.

Existem três tipos comuns de torneiras:

● Torneiras manuais – usadas manualmente com cabo em T

● Machos de ponta espiral – melhores para furos passantes

● Machos de canal espiral – melhores para furos cegos

Os machos geralmente são específicos para um tamanho de rosca e passo, o que os torna convenientes, mas rígidos em termos de flexibilidade.

O que é fresamento de roscas?

O fresamento de roscas, por outro lado, utiliza uma ferramenta rotativa chamada fresa de roscas para cortar roscas com um movimento de interpolação helicoidal. A ferramenta entra no furo e segue um caminho espiral para formar a rosca, usando um programa CNC para controlar o passo e a profundidade.

Existem três tipos de fresas de rosca:

● Fresas de rosca de ponto único – extremamente flexíveis para roscas personalizadas

● Fresas de rosca multiformas – cortam o perfil completo em uma única passagem

● Fresas de rosca indexáveis – ideais para grandes roscas ou séries de produção

O fresamento de roscas pode exigir mais tempo de programação e configuração, mas se destaca em áreas que o rosqueamento simplesmente não consegue alcançar.

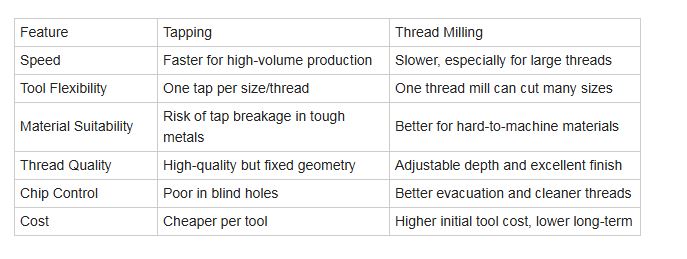

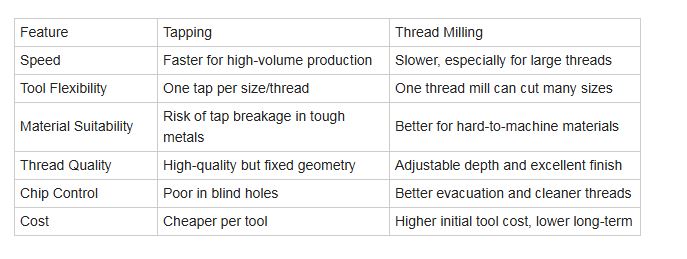

Fresamento de Rosca vs Rosqueamento: Comparação Direta

Vamos comparar fresamento de roscas com rosqueamento nas áreas mais importantes:

Fresamento e Rosqueamento em Diferentes Materiais

Ao trabalhar com materiais mais macios, como alumínio ou aço macio, a perfuração é rápida e raramente problemática.

Mas quando se trata de:

● Aço inoxidável

● Aço para ferramentas

● Superligas

…o fresamento de roscas proporciona maior vida útil da ferramenta e reduz o risco de quebra. Isso o torna uma escolha inteligente para as indústrias aeroespacial, médica e de alta precisão.

Diferenças na programação CNC

A batida geralmente depende de um ciclo simples (G84 para a mão direita, G74 para a mão esquerda). Fácil de programar, com variáveis mínimas.

O fresamento de roscas, por outro lado, requer:

● Interpolação circular (G02/G03)

● Controle de profundidade

● Programação de ângulo de hélice

Embora isso adicione complexidade, os softwares CAM e CNCs modernos tornam isso cada vez mais fácil.

Considerações sobre custo e vida útil da ferramenta

Os machos se desgastam rapidamente em materiais duros e podem quebrar, especialmente em furos cegos com baixa evacuação de cavacos.

As fresas de rosca, embora mais caras no início, duram mais e são mais flexíveis, especialmente se você estiver rosqueando perto da base de um furo. Além disso, se uma fresa de rosca quebrar, normalmente você não perde a peça inteira.

O fresamento de roscas é melhor que o rosqueamento?

Depende da sua aplicação.

O toque vence quando:

● Você está trabalhando em produção de alto volume

● O tamanho e o material da rosca são padrão

● A velocidade e o custo por furo são essenciais

O fresamento de roscas é melhor quando:

● Você está rosqueando materiais caros ou difíceis como Inconel ou titânio

● Você precisa de flexibilidade em tamanhos ou profundidades de rosca

● Você quer evitar quebrar torneiras em furos cegos

● Você está usando máquinas CNC capazes de interpolação helicoidal

Então, o fresamento de roscas é melhor do que o rosqueamento? Em termos de flexibilidade e segurança, sim. Mas em termos de velocidade e simplicidade, o rosqueamento ainda é o melhor para o trabalho diário.

Na KESO, somos especialistas em peças roscadas precisas e confiáveis, independentemente do tamanho, material ou método de rosqueamento. Se você precisa de ajuda para programar um ciclo de fresamento de roscas ou deseja uma produção de rosqueamento em massa, estamos aqui para ajudar.

Carregue seu arquivo de design e receba um orçamento gratuito aqui. Recomendaremos o melhor processo para seu trabalho.

Palavra final: qual você deve usar?

Use a técnica de toque quando:

● Você precisa de rapidez e baixo custo

● Você está trabalhando em grandes lotes com threads consistentes

● Você tem capacidades CNC limitadas

Utilize fresamento de rosca quando:

● Você está trabalhando com materiais resistentes ou caros

● Flexibilidade, precisão e qualidade da rosca são importantes

● Você está rosqueando furos cegos ou variando diâmetros de rosca

Dica profissional: se você estiver rosqueando peças críticas, teste os dois métodos. Um único macho quebrado pode custar mais do que investir em uma fresadora de roscas.

ASSINE NOSSA NEWSLETTER

ASSINE NOSSA NEWSLETTER